Product Details

Product Introduction

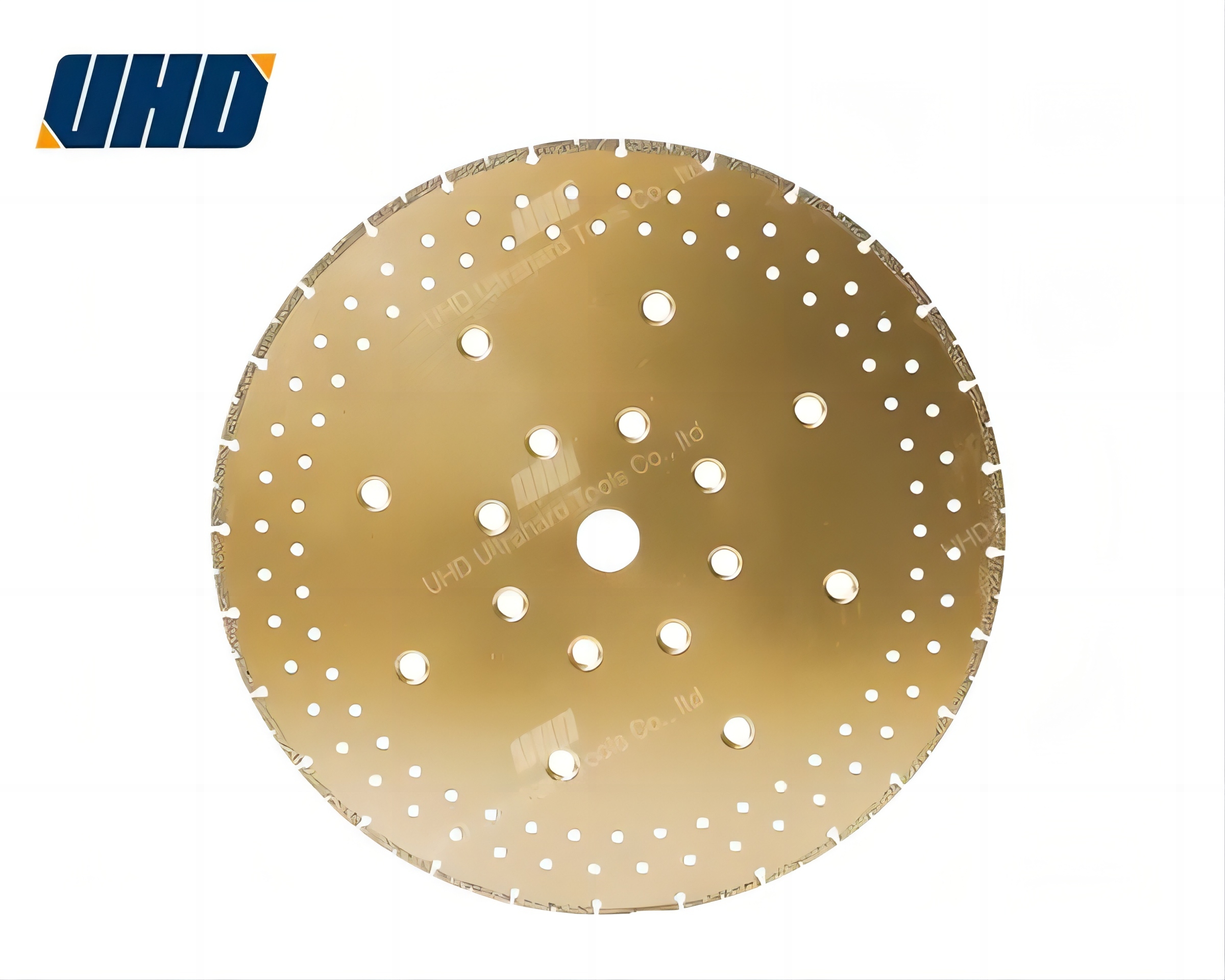

UHD Superhard Material Tools Co., Ltd. specializes in vacuum-brazed, high-performance diamond cutting tools designed for the metal and stone manufacturing industries. They operate within a wide temperature range (0°C to 120°C) and ensure stable and efficient cutting performance. Advanced vacuum brazing technology improves the tool's bond strength and durability, significantly extending its service life and reducing production line downtime. Available with a diameter of 200mm and an M18 connection interface, these tools flexibly meet the needs of diverse equipment. With precision manufacturing processes and innovative designs, these tools excel in complex industrial environments. UHD adheres to international quality standards and leverages its strong R&D capabilities to provide global customers with personalized customization and professional technical support, ensuring both improved processing quality and production efficiency. Choose UHD products to build efficient and reliable cutting solutions that empower your manufacturing business to continue growing.

Advantages and features

1. Advanced vacuum brazing process, high bonding strength, improved tool stability and life.

2. Wide operating temperature range (0°C-120°C), adaptable to various complex industrial environments.

3. Multi-specification design, 200mm diameter and M18 connection interface meet the needs of diverse equipment.

4. Precision manufacturing and innovative design ensure cutting efficiency and processing quality.

5. Reduce downtime and improve the overall efficiency and economic benefits of the production line.

6. UHD brand guarantee, providing customized services and comprehensive technical support.

Application Scenario

Widely used in metal manufacturing, stone processing, machinery manufacturing, architectural decoration, and industrial cutting, the 1000 series is ideal for metal fabrication, stone mining and processing, machinery manufacturers, and other industrial users requiring high-efficiency cutting tools. It excels in applications where efficiency needs to be improved, tool life extended, and downtime reduced.