Product Details

Product Introduction

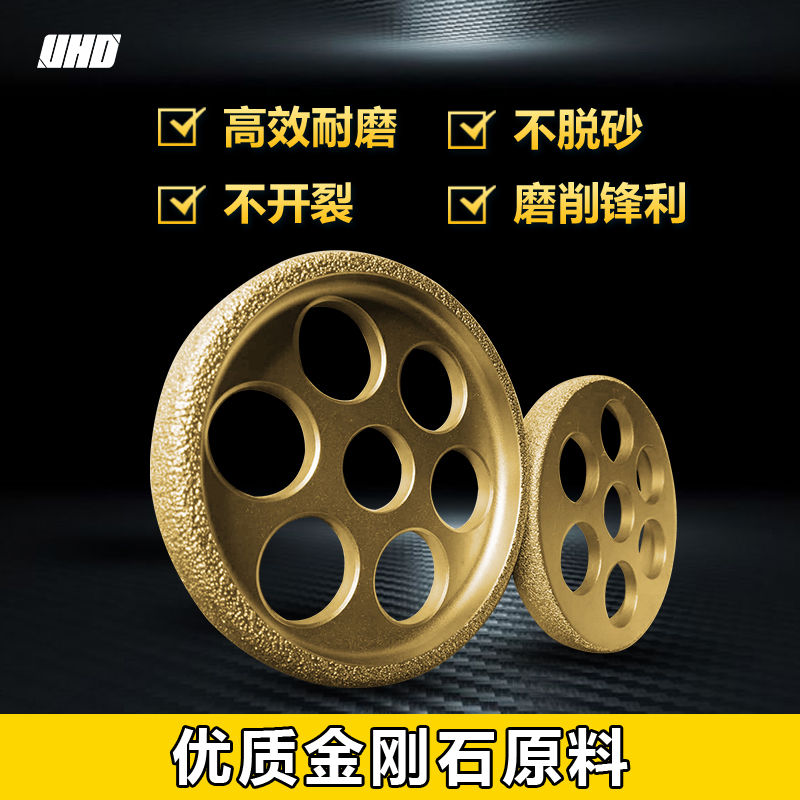

Henan UHD Superhard Tools Co., Ltd. (UHD) produces high-performance vacuum-brazed diamond grinding wheels, utilizing high-quality diamond materials combined with an advanced vacuum brazing process to achieve high-strength bonded grinding wheel grains and exceptional wear resistance. Available in sizes ranging from 300mm to 405mm, these precision-designed wheels are suitable for machining a variety of hard materials, including ductile iron, gray iron, ceramics, and rubber. Optimized processes effectively reduce dust emissions during the grinding process, ensuring a safe working environment and complying with international environmental standards. UHD adheres to a strict quality management system, and its products have obtained CE and intellectual property management certifications. They combine high-efficiency grinding with environmental performance, significantly extending tool life. We also offer flexible after-sales support, including a 7-day, no-questions-asked return policy and a warranty of up to 12 months, to help customers achieve efficient and stable industrial production.

Advantages and features

1. Advanced vacuum brazing technology ensures a secure bond between diamond particles, enhancing wear resistance and service life. 2. Precise dimensional control allows compatibility with a wide range of equipment specifications, minimizing material loss. 3. Optimized design reduces grinding dust, meeting international environmental and safety standards. 4. Compatible with a wide range of materials, including hard materials such as ductile iron, gray iron, ceramic, and rubber. 5. CE and intellectual property management system certification ensure strong quality assurance. 6. Comprehensive after-sales service offering a 7-day, no-questions-asked return policy and a warranty of up to 12 months.

Application Scenario

Suitable for industrial abrasive tool manufacturers and metal and non-metal hard material processing companies, it is particularly well-suited for ductile iron and gray iron parts processing and ceramic polishing. It is widely used in automotive manufacturing, mechanical processing, mold making, rubber material finishing, and precision hardware processing, helping customers improve processing efficiency and product quality.